M.A.P Safety System

Stairwell Hatch – Modular Access Platform Safety System

|

|

Stairwell Hatch – Modular Access Platform Safety System

|

|

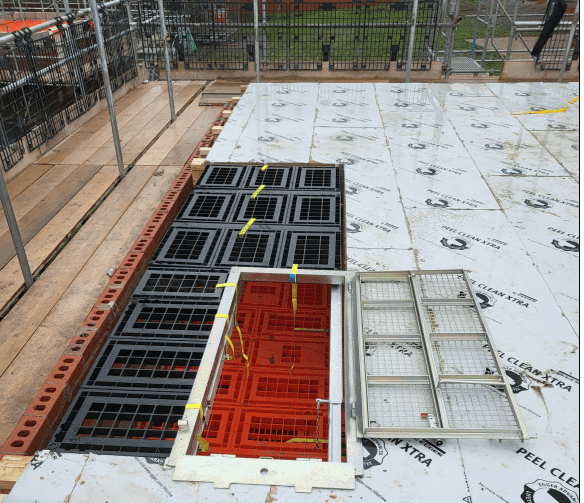

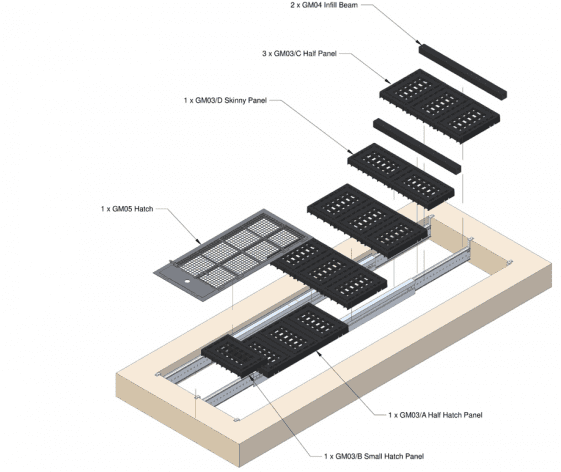

Our M.A.P Safety System is unique design, a modular access platform designed to offer a flush cover platform over various size voids. This prevent falls whilst providing full or partial access for operatives and materials. It is suitable for use in a wide range of construction environments.

Researched and developed by us we are proud to offer the one of a kind M.A.P Safety System which has a range of unique design features, including:

The system can be used in stairwells ranging from 2 – 4 meters in length and of any width. It is also suitable for use in L-shaped stairwells. Openings next to party walls are no problem and the system allows full or partial access for both operatives and materials.

The M.A.P Safety System is installed at the earliest stages of construction; directly after the joists or other load bearing members have been fitted. What’s more, our system can be used in conjunction with ladders or temporary stairs.

If you’re looking for a stairwell hatch that is quick and easy to install, our M.A.P Safety System is the perfect choice.

It’s lightweight, modular design means that it can be installed with ease by one person in approximately 10 minutes making it much more cost-effective compared to installing sacrificial joists and flooring over stairwell voids.

We are proud of our safety standards and that our M.A.P system is manufactured in the UK. Including the stairwell hatch which has undergone rigorous testing by Lucidean testing house and exceeds Health & Safety Executive standards.

G&M Safe Deck’s unique design allows a tube or scaffold to be built through any part of the panels making is flexible and quick to install on site.

Yes, we can manufacture the Safe Deck panel components in any colour to meet your requirements. We can also brand the panels with your company logo and contact details for buying customers, enabling you to promote your company whilst on site. Simply discuss your colour and branding requirements with a member of our sales team.

Yes, the full size panel can be cut in half, thirds, two-thirds or sixths. The Safe Deck panel is designed to be cut down without loss of rigidity or strength. Consequently the panel can be re-used even if it is damaged. Thereby cutting down on waste and loss.

Yes, the G&M Safe Deck system can be set-up as freestanding. It is the only plastic freestanding decking system available in the UK.

In one easy application, involving a simple component that can be quickly and easily pinned to either end of a leg tube, G&M Safe Deck can be made freestanding, meaning that there is no need for the supporting structure to contain the deck.

G&M Safe Deck has undergone rigorous testing by Lucideon (formerly CERAM – a UKAS accredited testing (0013) and calibration. (0420) UK laboratory) and can be loaded to 2.0kN/m2.

The safety decking panel has been successfully tested for:

For more information on G&M Safe Deck’s load testing methodology and data, download our product information sheet here.

Yes. G&M Safe Deck Ltd care a great deal about our customers and the support we provide them. Consequently we listen to what our customers want. We were asked by our customers for a Safe Deck half panel they could purchase as a separate item as and when they needed them. As a result of this we have gone into R&D and developed a half panel. The Safe Deck half panel has been tested by a UKAS accredited test centre. Consequently we have testing data which proves the Safe Deck half panel has the same loading capability and characteristics as the standard full size panel.

Safety decking plays a crucial role in promoting sustainability on construction sites.

Safety decking plays a crucial role in protecting construction workers by providing a secure working platform at elevated heights. Here’s how safety decking safeguards workers:

Preventing Falls: Safety decking creates a stable and level surface for workers to stand or walk on while performing tasks at heights. This minimizes the risk of falls, which is one of the most significant hazards in construction.

Fall Arrest: In the event of an accidental slip or trip, safety decking is often designed to act as a fall arrest system. It can stop a worker from falling to a lower level, reducing the severity of injuries or preventing them altogether.

Enhancing Stability: Safety decking is engineered to support the weight of construction workers, equipment, and materials. This stability ensures that workers can carry out their tasks without worrying about the platform collapsing or shifting.

Increased Confidence: Knowing they are working on a secure surface, workers can concentrate on their tasks with greater confidence and peace of mind, reducing stress and distraction that can lead to accidents.

G&M Safe Deck has been designed to be lightweight as well as strong. A full size panel weighs 10.43 kg.

The G&M Safe Deck System has a proven life expectancy of at least 10 years. This has been proven by testing panels taken from our contracting stock that are 10 years old. The testing was successful and the old panels performed as well as a new one would. G&M Safe Deck is by far the most rigorously tested plastic system available on the market anywhere in the world.

G&M Safe Deck exceeds all Health and Safety Executive Standards and provides an exceptionally safe platform for working at height.

The system is tested to BS5973:1993, BSEN12811-1: 2003 and ACR [M] 001:2014 as stipulated by FASET.

For more information on G&M Safe Deck’s testing methodology and data, download our product information sheet here.

As an accredited FAEST training centre, G&M Safe Deck offer training courses for both platform decking installers and managers.

The FASET Platform Decking Installer course is designed for operatives, however, it is also suitable for anyone who wishes to learn how to install platform decking safely and in a compliant manner. This course covers planning, installation, and the practical issues for the correct use of platform decking on site.

The FASET Platform Decking Managers course is designed for the site manager. It will help platform decking managers to better understand the limitations of individual systems, enabling them to inspect platform decking systems correctly and manage their use on site.

For more information about our FASET Platform Decking courses for the G&M Safe Deck system, click here

Safety decking is beneficial in a construction project for a multitude of reasons. Its primary function is to safeguard the well-being of construction workers, mitigating the risks associated with working at heights. Here are several key reasons why safety decking is beneficial:

We provide full onsite assessment backed by a professional and highly experienced team to ensure your site personnel are safe from the start of the job until evacuation.

Contact the Team today for a quote

G&M Safety Netting Ltd, 7a Brooks Lane, Middlewich, Cheshire, CW10 0JH

T: 01606 834 630E: office@gmsafedeck.co.uk